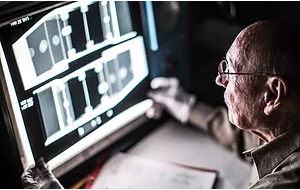

RADIOGRAPHIC INSPECTION

Industrial radiography is a method of non-destructive testing where many types of manufactured components can be examined to verify the internal structure and integrity of the specimen. Industrial Radiography can be performed utilizing either X-rays or gamma rays. Both are forms of electromagnetic radiation. The difference between various forms of electromagnetic energy is related to the wavelength. X and gamma rays have the shortest wavelength and this property leads to the ability to penetrate, travel through, and exit various materials such as carbon steel and other metals.

ULTRASONIC INSPECTION

Ultrasonic testing techniques are based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion.. . .

MAGNETIC PARTICLE INSPECTION

MPI is a process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials. The process of magnetization occurs when electric current is passed through the test object. The presence of a surface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals. To identify a leak, ferrous particles, either dry or in a wet suspension, are applied to a part. These are attracted to an area of flux leakage and form what is known as an indication.

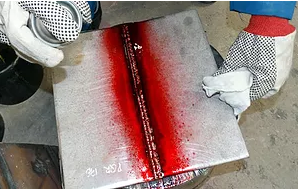

DYE PENETRANT INSPECTION

PT is a widely applied inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components. . .

About Us

CONTRACT INSPECTION SERVICES cc., a comprehensive non-destructive testing and engineering inspection authority was formed in January 1986.

Contract Inspection Services is a leader in the non destructive testing (NDT) industry by providing a wide array of conventional and state of the art analysis techniques to evaluate materials and systems.

Our technical and engineering teams contain qualified inspectors to perform Magnetic Particle Testing (MT), Ultrasonic Testing (UT), Radiographic Testing (RT), Liquid Penetrant Testing, (PT) Visual Testing (VT), Weld Inspection (WI) and Specialized Material Analysis that conforms to nationally recognized codes or can be tailored to our clients specific needs.

Services

-

Radiographic Testing

-

Ultrasonic Inspection

-

Magnetic Particle Inspection

-

Dye Penetrant Inspection

-

Hardness Testing

-

Wall Thickness Testing

-

Fluorescent Penetrant Testing

Welding Documentation

-

Welding Inspection

-

Welding Procedures Specifications

-

Welders Qualification Certificates

-

Procedure Qualification Record

-

Mechanical Testing

-

Quality Control

Technicians

All our technicians are suitably experienced and independently approved s.a.q.c.c. and asnt-tc-1a standards and have at their disposal, the necessary equipment with various source strengths to suit any application.

All our technicians are fully conversant and comply with the regulations as gazetted by the atomic energy corporation.

Our Team

History

Management